CASE STUDY

Transforming Waste to Feed Using ‘Paused’ Black Soldier Fly (BSF) Neonates

Unlocking Waste Management Potential: FreezeM’s & Shachar’s Decoupled Model Paves the Way for Insect Bioconversion

The Problem:

As a company focused on upcycling food waste, Shachar successfully converted many types of waste streams into animal feed. These streams primarily consist of relatively dry products (such as bread or expired snacks), which can be upcycled to animal feed after depacking and initial processing.

However, wet waste streams are less favorable to this process as their shelf life is much shorter and they contain a higher percentage of water that makes hauling less economically efficient.

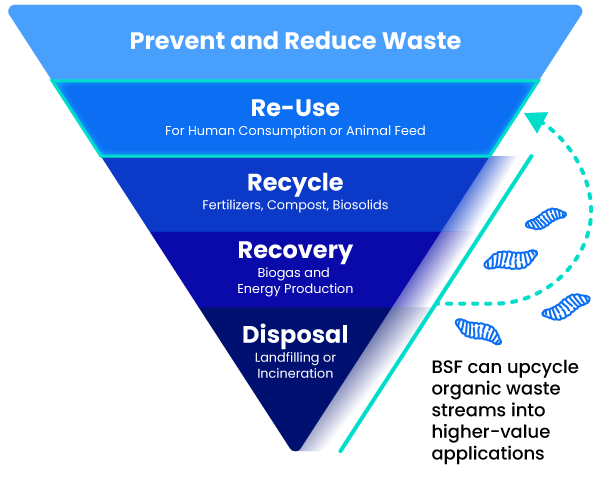

Wet waste streams are usually directed to biogas or other energy production applications and thus are less favorable to waste-to-feed companies. In addition, such applications usually miss the upcycling potential of the organic waste source as energy is lower than animal feed in the waste management hierarchy (see image below in the page).

While BSF bioconversion is an excellent solution for treating wet waste streams (as BSF feed is usually 60-70% wet), maintaining a fly colony in a waste management factory is not usually feasible.

The Solution:

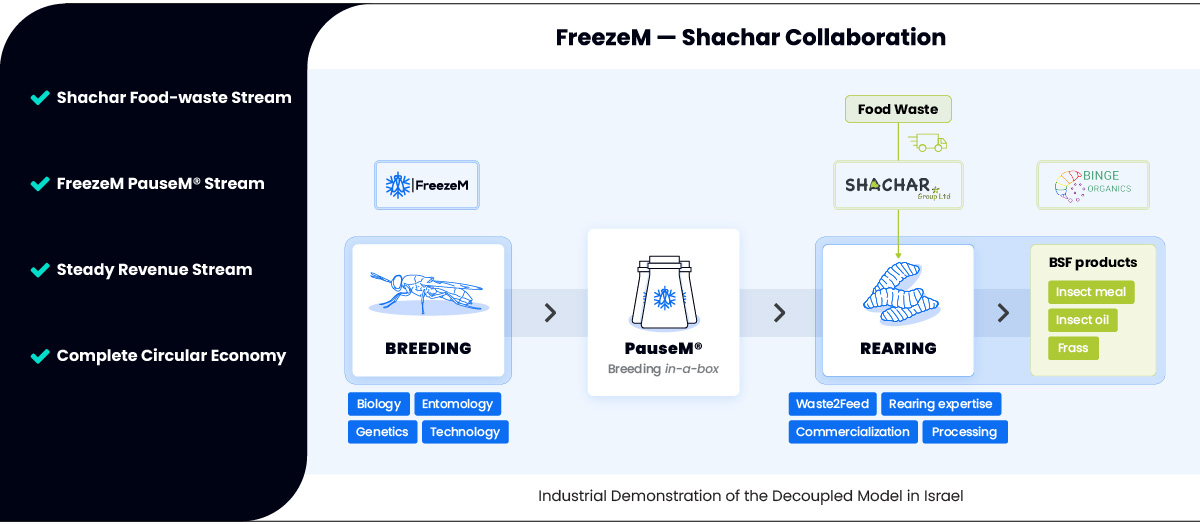

FreezeM’s decoupled model, which offers outsourced breeding supply to insect production facilities, perfectly aligns with Shachar’s strategic goal of entering the BSF farming sector while leveraging their strengths in waste management and industrial operations. This strategic partnership mitigates risks associated with specialized biological processes and allows both parties to maintain focus, drive efficiency, and achieve their goals in this new venture.

In this model, FreezeM regularly supplies Shachar with PauseM® BSF neonates, facilitating the establishment and expansion of BSF production within an existing factory (bring the larvae to the waste and not the waste to the larvae), eliminating the need for a breeding unit. This makes the entire process more scalable, cost-effective and efficient.

Shachar Group and FreezeM have joined forces to revolutionize waste management through innovative Black Soldier Fly (BSF) technology. Shachar specializes in the treatment and recycling of industrial & commercial food waste into animal feed as well as BSF rearing through its subsidiary Binge Organics, which specializes in formulating and rearing BSF on diets sourced from food waste, while FreezeM streamlines the insect protein production process through its Breeding-as-a-Service model. Together, they’re transforming food waste streams into valuable resources, creating a sustainable solution for environmental preservation and economic growth.

How Does it Work?

In order to create the technological infrastructure of converting waste to insect protein at scale, Shachar has built a state-of-the-art pilot rearing facility, with the aim of conducting R&D activities and exploring various waste streams from the food industry, understanding their advantage in insect bioconversion compared to other WM applications, such as anaerobic digestion and composting, and preparing optimal BSF feed recipes. This pilot facility is fully integrated into Shachar’s food waste recycling factory and focuses only on the rearing and processing parts of the BSF supply chain.

FreezeM supports this activity by providing Shachar with its novel product PauseM® – ready-to-use suspended BSF neonates with an extended shelf life of over 21 days and at least 90% survival rate. PauseM® units, containing up to 50k, life-suspended neonates each, are shipped once a week from FreezeM’s breeding hub to Shachar’s pilot rearing facility. The neonates are activated according to the production needs and used to evaluate various waste-based recipes in industrial scale and settings.

PauseM® is accurately dosed, enabling precision and reproducibility. The ongoing support and collaboration between the teams made it possible to develop world-leading food waste-based feed recipes for BSF and use them to reach a superior feed conversion rate (FCR), reduced rearing time, tremendously low cost, qualified by EU current regulation and reach extremely high larvae yields.

A Collaboration for Innovative Sustainable Waste Management & Recycling

The ongoing efforts have laid the foundation for the next phase of the project, where Shachar is establishing an industrial-scale beta site scheduled to commence operations as early as next year.

The ultimate vision of this collaboration is to erect a cutting-edge facility capable of processing an astounding 300 tons of food waste daily. This facility signifies a groundbreaking move towards a more efficient and eco-conscious future, showcasing a steadfast commitment to innovation, sustainability, and the creation of new revenue streams.

Collaborative Success

- FreezeM’s PauseM® technology has become indispensable to waste management operations, amplifying efficiency and sustainability.

- This collaboration underscores the effectiveness of decoupling BSF Breeding from rearing and processing, enabling waste management companies to participate in a scalable circular economy at a reasonable cost while generating new revenue streams.

- This collaboration, based on synergy between companies specializing in different parts of the supply chain, has already resulted in superior KPIs compared to the industry benchmark. For example, we managed to demonstrate a consistent yield of over 9kg of grown larvae in 10-12 days from one PauseM unit containing 50k neonates, while using food waste-based recipes with a close to zero cost per ton (compared to 30 Euro/ton price used by some BSF producers in Europe).

- The partnership between Shachar and FreezeM is reshaping waste management practices, presenting a new opportunity to upcycle qualified organic waste streams into higher-value applications in the waste management hierarchy, such as protein for animal feed and organic fertilizer for agriculture.

Conclusion

Shachar and FreezeM’s collaboration exemplifies the power of innovation in waste management. By harnessing BSF technology, they’ve created a sustainable solution that addresses not only environmental concerns but also generates new revenue streams and fosters economic growth. Through continued partnership and innovation, they pave the way for a greener, more sustainable future.

About Shachar Group

Shachar Group, as the largest food waste upcycling company specializing in the treatment and recycling of industrial, commercial and institutional food waste in Israel, recycles more than 70,000 tons per year. Their operations not only contribute positively to the environment but also offer a cost-effective sustainable solution to their expanding customer base. Shachar’s unique approach encompasses the storage, transportation, and upcycling of this waste, ensuring a zero waste process that converts food waste into valuable products.

Furthermore, Shachar strategically invests in new technologies aimed at enhancing value creation from waste streams. This strategic investment aligns with their mission to continuously innovate and optimize their waste management processes while delivering sustainable solutions to them.